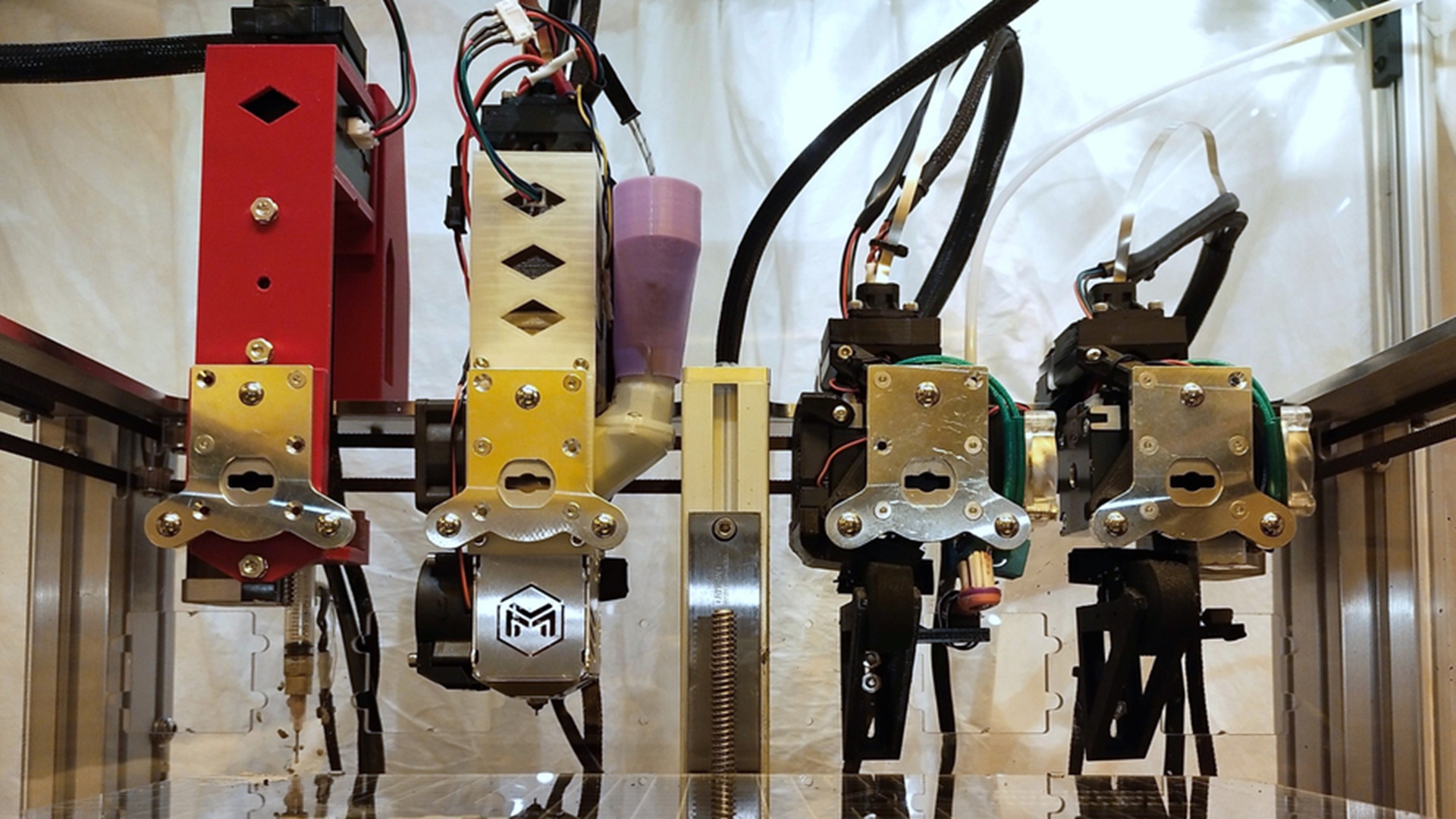

Multimaterial 3D printer builds working motor from scratch in hours

Key Points:

- MIT researchers have developed a 3D-printing platform capable of fabricating fully functional electric machines in a single process, potentially enabling on-site production of replacement motors within hours.

- The system uses multimaterial extrusion with four extruders to print devices composed of conductive, magnetic, and structural materials, demonstrated by printing a working electric linear motor in about three hours.

- The printed linear motor, made from five materials and requiring only magnetization as post-processing, showed performance several times greater than comparable hydraulic-based linear engines, with an estimated material cost of around 50 cents.

- This technology aims to decentralize manufacturing by allowing localized, integrated production of complex electromechanical devices, reducing dependence on global supply chains and minimizing factory downtime.